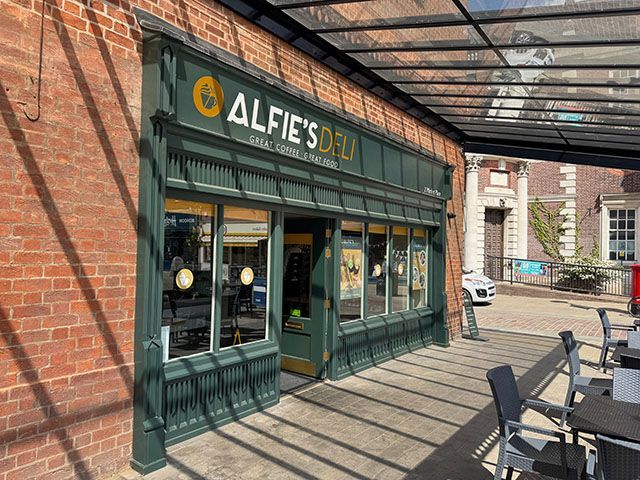

As part of the overall project a large portion of it was the creation of a glazed canopy to the Market Place Elevation of the Old Town Hall which would create a covered area in front of the new shopfronts.

The removal of the existing canopy in itself caused issues due to a large amount of steel beams being connected to a large internal steel beam within the Old Town Hall. Due to the fact the Market Place is a bustling and busy public space the need to protect the public and cordon off the work area’s while maintaining access to the businesses was challenging. It was decided that certain parts of this removal were carried out after working hours so the area was quieter and the shops unaffected by the removal work

.

When it came to the installation of the new design, 9 separate padstones had to be excavated to a depth of approximately 1200mm, each area had to be CAT scanned beforehand due to the presence of underground Telecoms, Gas and Electric services. The building inspector was then called in order to sign off the ground conditions for concreting.

Once the concrete had been poured and cured it was time to install the 9 columns these came pre finished to a RAL colour chosen by the project management team, this meant that a lot of care had to be taken with the fitting in order not to damage the finish.

With the columns bolted in position the eaves beams were bolted together and to the top of the columns with raking steels bolted back to the building to make sure the structure was secure. This was carried out in meticulous detail to the Structural Engineer design.

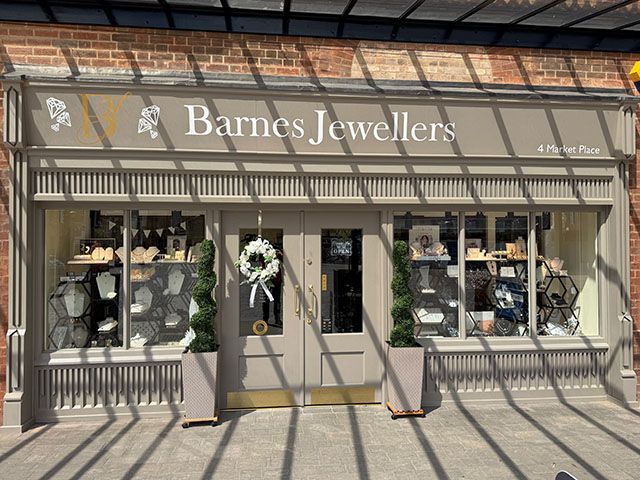

The next stage was to fit the Architectural Metalwork onto the Canopy steelwork. This was cast aluminium frieze at eaves level and at flashing level as well as column castings at low and high level which transformed the industrial looking steelwork into a stunning architectural structure.

The final stages of the canopy installation was the fitting of Bespoke Architectural Glazing. Carre Heritage spoke with numerous companies and decided upon The Standard Patent Glazing Company, working with their surveyors on the final site measure it was found that from end to end (over 30 metres) the steel eaves beams were parallel to the building and within 7mm out of a 15mm tolerance allowance!

The glazing panels were 6mm toughened glass that had a solar film applied, the glazing bars were powder coated to match the colour of the metal work of the canopy.

Finally the powder coated aluminium ogee guttering and rainwater pipes were fitted ensuring the canopy was fully weatherproof and directing all rainfall into the existing surface water system.